Expansion joints are critical in engineering and construction. They absorb movement from temperature changes, ground settling, or structural stress. Among many materials, rubber stands out for its flexibility and durability. Therefore, expansion joint rubber is widely used in many industries.

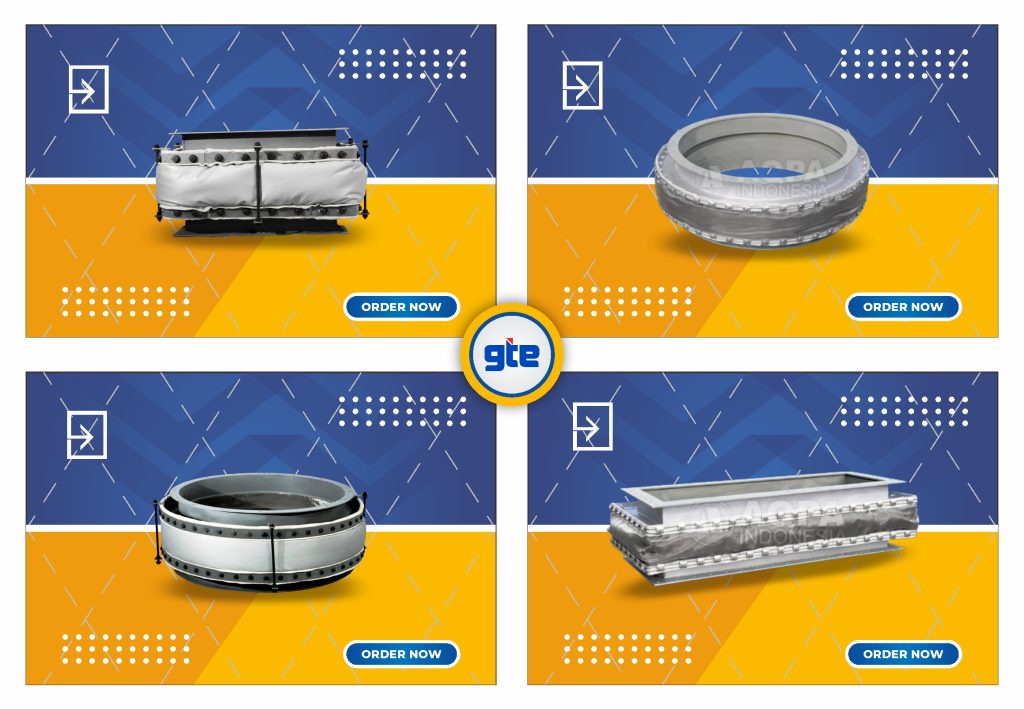

Rubber Expansion Joint fills the gaps between structural elements. It provides flexibility and seals joints against water or debris. Available as sheets, strips, or custom profiles, it resists harsh environments. This makes it ideal for maintaining structural stability in various applications.

Let us now explore its types, applications, and key advantages.

Rubber Expansion Joint comes in various materials, each with distinct properties:

Neoprene : Resists weather and is ideal for outdoor use.

EPDM : Withstands heat, ozone, and weathering in construction.

SBR : Offers resilience at a low cost for general uses.

Silicone : Perfect for extreme temperatures and specialized industries.

Natural Rubber (NR) : Highly elastic and used across many industries.

Nitrile (NBR) : Resists oils, fuels, and chemicals in harsh environments.

Each type meets specific application needs, offering performance and durability.

Rubber Expansion Joint serves multiple industries due to its versatility:

Bridges and Highways : Allows structural movement without damage.

Piping Systems : Prevents leaks while handling thermal expansion.

Buildings : Supports skyscrapers and large structures against stress.

Roadways : Absorbs concrete movement to prevent cracking.

Marine and Offshore : Withstands water and salt exposure effectively.

These applications highlight its role in maintaining safety and durability.

Flexibility and Movement Accommodation

Rubber expansion joints are designed to allow for significant movement up to 30 mm and angel up to 20⁰ due to thermal expansion, contraction, and structural settling. This flexibility helps prevent cracks and structural damage.

Vibration and Shock Absorption

Rubber effectively absorbs vibrations and shocks, protecting the integrity of structures and extending the lifespan of equipment and joints.

Durability

High-quality rubber is resistant to wear, chemicals, and UV exposure, making it suitable for both indoor and outdoor applications. This durability ensures that the joints remain effective over time, even under harsh conditions.

Noise Reduction

The acoustic dampening properties of rubber help to minimize sound transmission, making environments more comfortable, particularly in industrial and commercial settings.

Cost-Effectiveness

By preventing damage and maintenance costs, expansion joint rubber is a cost-effective solution in the long run. Its durability and performance reduce the need for frequent replacements.

Easy Installation

Many rubber expansion joints are designed for straightforward installation, which can help reduce labor costs and project timelines.

Rubber Expansion Joint plays a key role in protecting structures from stress. Its flexibility and strength prevent cracks, leaks, and costly damage. The material adapts well to diverse industrial needs, ensuring long-term stability.

As industries evolve, demand for reliable rubber joints will grow. They remain vital in modern infrastructure projects. Therefore, understanding their use can help you make better decisions in construction and engineering.

For tailored solutions or further information, feel free to contact us anytime.

Why Choose Us as Your Partner?

We are a trusted Rubber Expansion Joint provider with years of experience in the industry. We offer a wide range of Rubber Expansion Joint types and sizes to meet your unique needs. Our products are made from high-quality materials and manufactured to stringent standards to ensure optimal performance and customer satisfaction.

Feel free to our team if you have any questions or wish to order our product. We are ready to assist you in finding the right sealing solution for your application. We hope this article provides valuable insights, If you have any further questions, please do not hesitate to contact us.