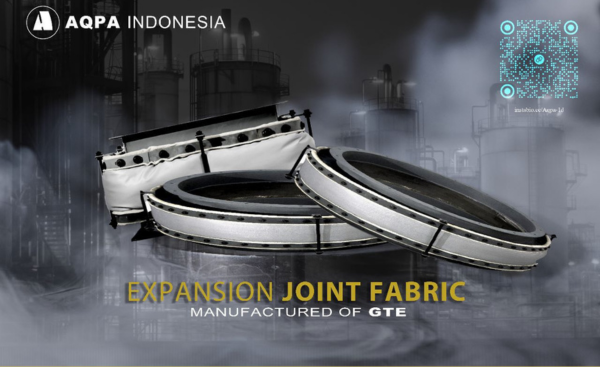

Fabric Expansion Joint — Flexible Solution for Industrial Piping Systems

Fabric expansion joint play a vital role in various industrial systems. They help absorb movement, vibration, and misalignment in ducting and piping. Unlike metal joints, fabric expansion joints offer excellent flexibility and adaptability.

These joints are used in systems that handle gases at moderate pressures and temperatures. They provide reliable sealing and compensate for thermal expansion or structural movement. As a result, they help protect connected equipment from stress and damage.

Let us explore their structure, advantages, and applications in more detail.

A fabric expansion joint connects two ducting systems and absorbs movement between them. It uses layers of flexible materials like PTFE, fiberglass, or silicone-coated fabrics.

The design allows the joint to stretch, compress, or twist without losing its seal. This flexibility ensures consistent performance even under varying conditions.

Typically, these joints handle movements caused by thermal expansion, vibration, and mechanical shifts.

This product offer several clear benefits for industrial use:

High Flexibility: They easily accommodate axial, lateral, and angular movements.

Lightweight Design: Their lightweight structure makes handling and installation simpler.

Corrosion Resistance: Fabric materials resist chemicals, moisture, and aggressive gases.

Noise and Vibration Dampening: They reduce noise transmission and absorb system vibrations effectively.

Cost Efficiency: Lower material costs and easier installation reduce overall project expenses.

These features make fabric expansion joints a popular choice in many industries.

Applications of Fabric Expansion Joint

These joints are widely used in various sectors. Below are some key applications:

Power Plants: Installed in flue gas ducts to handle thermal expansion and vibration.

Refineries: Used in exhaust systems and ducting for oil and gas processing units.

Chemical Plants: Applied in ventilation and exhaust systems exposed to corrosive substances.

Cement Industry: Used in kiln exhaust systems to manage heat and structural shifts.

Steel Industry: Installed in gas cleaning systems and ductwork for furnaces.

Their versatility makes them essential in harsh industrial environments.

Final Thoughts

This product offer flexible, durable, and cost-effective solutions for industrial ducting systems. Their ability to absorb movements and vibrations helps protect piping and equipment.

By choosing the right materials and design, industries can maximize system performance and lifespan. As operational demands increase, fabric expansion joints remain a vital component for reliable industrial systems.

Why Choose Us as Your Partner?

We are a trusted provider with years of experience. Our products meet high-quality standards and suit various applications. We offer a wide range of options tailored to your needs.