Fabric Expansion Joint is a flexible component used to absorb thermal expansion, vibrations, and mechanical movement in industrial ducting and piping systems. Typically, it’s made from a combination of technical fabrics such as fiberglass, silica cloth, or PTFE (Teflon), layered with heat- and chemical-resistant materials.

These layers are specifically engineered to withstand high temperatures, reduce vibrations, and remain flexible under continuous pressure. In other words, this product acts as a silent protector, ensuring the integrity of the system.

Every piping or duct system experiences movement — whether from temperature shifts, pressure changes, or mechanical vibrations. Without proper handling, joints may become damaged or lead to leaks. Therefore, Fabric Expansion Joint is crucial for maintaining system safety.

Its main functions include:

- Absorbing expansion and contraction due to temperature

- Dampening vibrations from machines

- Preventing cracks or dislodging at pipe joints

As a result, systems run more safely, efficiently, and with reduced downtime.

Fabric expansion joints are manufactured using a variety of materials depending on the operating conditions, including :

- Heat resistant up to 550°C

- Lightweight and flexible

- Commonly used in HVAC and exhaust ducting

- Withstands temperatures up to 1000°C

- Ideal for boilers, turbines, and hot gas exhausts

- Resistant to chemicals and moderate heat (up to 260°C)

- Preferred in food, pharmaceutical, and chemical industries

- Used as insulation in multilayer systems

- Often inserted to protect inner layers from radiant heat.

Thus, each material serves a unique purpose based on technical challenges like temperature, pressure, or chemical exposure.

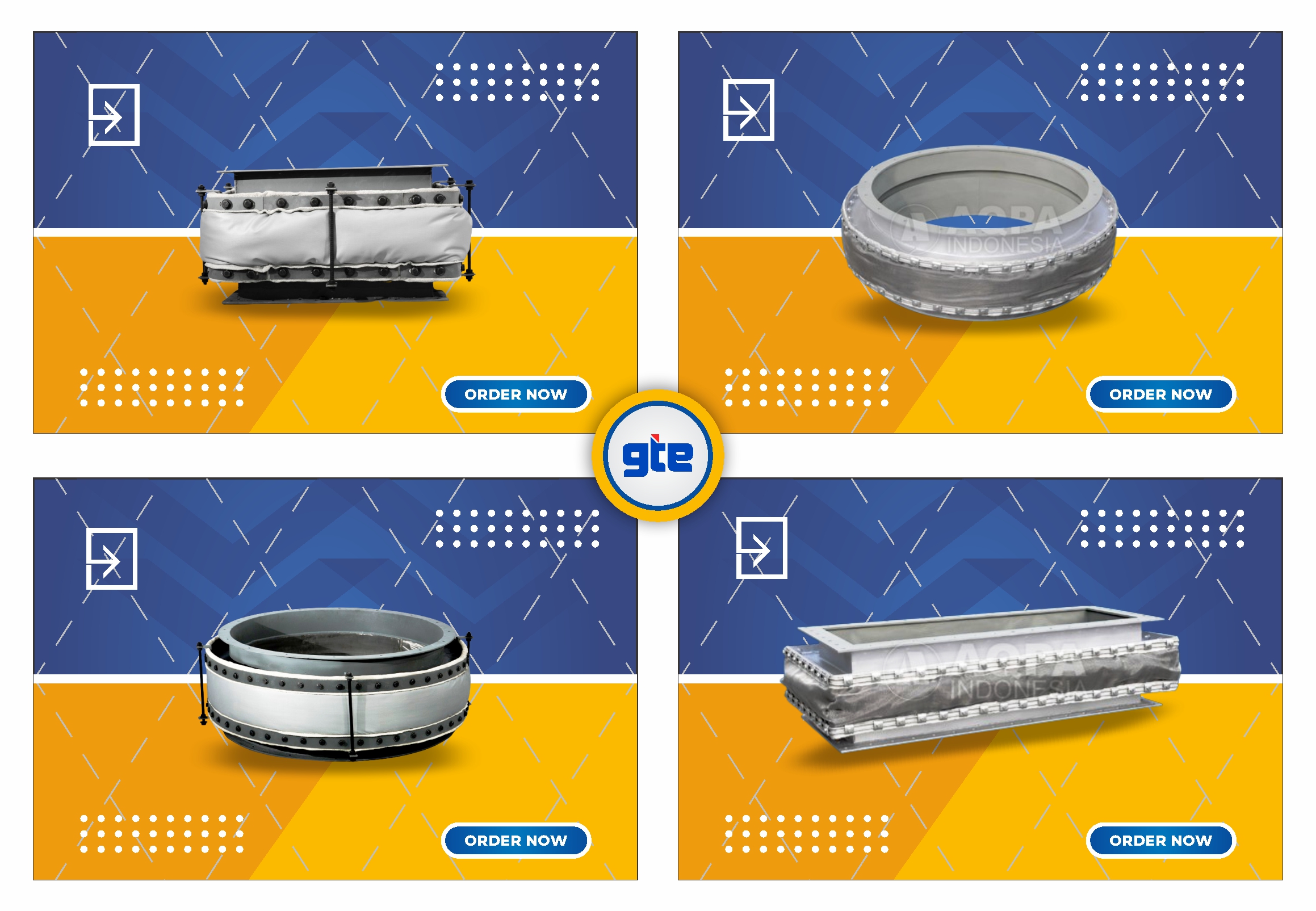

Typically, a fabric expansion joint consists of several layers:

- Inner Layer : directly contacts the airflow or gas

- Insulation Layer : helps resist high temperatures

- Reinforcement Layer : adds structural strength

- Outer Layer : protects from moisture, chemicals, and environmental factors

These layers are configured in flat or round forms depending on the system design. On the other hand, this structure offers great flexibility for installation across various applications.

Fabric expansion joints are engineered to absorb various types of mechanical movements in piping and ducting systems. These movements include:

- Axial Movement – Compression : A reduction in the face-to-face dimension of the expansion joint along its longitudinal axis.

- Axial Movement – Extension : An increase in the face-to-face dimension of the expansion joint along its longitudinal axis.

- Lateral Movement : A displacement of the inlet and outlet flanges perpendicular to the longitudinal axis of the expansion joint.

- Angular Movement : Occurs when one flange of the expansion joint shifts to a position that is no longer aligned with the opposite flange, creating an angular displacement.

- Torsional Movement : A twisting motion where one end of the expansion joint rotates relative to the other end along the longitudinal axis.

These capabilities make fabric expansion joints essential for maintaining system integrity and performance under dynamic operating conditions.

Fabric expansion joints offer several advantages over metal expansion joints, making them a preferred choice in many industrial applications :

Advantage | Description |

Flexible and Lightweight | Easy to install in tight spaces and complex structures |

High Temperature Resistance | Silica-based materials can withstand temperatures up to 1000°C |

Chemical Resistance | PTFE is ideal for aggressive gases and steam environments |

Durability | Long service life when operated within specified parameters |

Customizable | Can be tailored to meet specific project requirements |

Additionally, fabric expansion joints typically require lower maintenance due to their modular design, which allows for partial replacements.

To ensure optimal performance, fabric expansion joints must be installed with precision. Follow these steps:

- Ensure the flange or mating surface is clean and even.

- Position the expansion joint according to the gas flow direction (usually indicated by an arrow).

- Use bolts and clamps with uniform tightness.

- Avoid over-tensioning to allow the fabric to expand and contract naturally.

Proper installation significantly reduces the risk of leakage and premature wear.

To ensure optimal performance, fabric expansion joints must be installed with precision. Follow these steps:

Fabric expansion joints are widely used across various industries, including :

- Hot air ducts and chimneys

- Boiler and turbine connections

- Acid-containing exhaust gas lines

- High-temperature steam process installations

- Large ducting systems in malls, hospitals, and factories

- Clean air and exhaust air systems

- Exhaust gas systems

- Combustion air feed ducts

- Applications requiring high hygiene standards

- Use of food-grade materials like PTFE

In short, any industry involving hot air or gas flow relies on fabric expansion joints to prevent system failures.

To maximize service life, regular maintenance of fabric expansion joints is essential :

- Routine Visual Inspection : Check for cracks, delamination, or discoloration. Outer layers are often exposed to dust and hot gases.

- Light Cleaning : Use mild soap and a soft cloth. Avoid harsh solvents.

- Replacement : Replace the entire unit if the outer layer is damaged. Temporary patches are only recommended for emergency use.

Maintaining detailed inspection and maintenance records helps prevent unexpected downtime.

Before purchasing, consider the following factors:

- Type of Movement to be accommodated

- Operating Conditions : temperature, pressure, and chemical exposure

- Connection Type : flanged, belt-type, or clamp-type

- Size and Shape : custom designs for unique systems

- Certifications : such as ISO, FSA, or fire resistance ratings

Evaluating these criteria ensures the product meets your specific field requirements.

Fabric expansion joints may seem inconspicuous within piping systems, but their role is critical. With the ability to absorb movement, withstand extreme temperatures, and protect systems from mechanical stress, they are indispensable in heavy industries.

Choosing and installing the right expansion joint enhances system reliability, reduces risks, and extends the lifespan of the entire installation.

Why Partner with Us ?

We are a trusted this product provider with years of experience in the industry. We offer a wide range of this product types and sizes to meet your unique needs. Our products are made from high-quality materials and manufactured to stringent standards to ensure optimal performance and customer satisfaction.

Feel free to contact our expert team if you have any questions or wish to order this product. We are ready to assist you in finding the right solution for your application. We hope this article provides valuable insights, If you have any further questions, please do not hesitate to contact us.