Gland Packing : A Smart Solution to Seal, Protect, and Optimize Your Industrial Systems

In industrial operations, leakage represents a critical challenge that can cascade into equipment damage, production interruptions, and safety hazards. Whether dealing with pumps, valves, agitators, or rotating equipment, gland packing stands as a time-tested sealing solution that combines simplicity with reliability.

Gland packing, also known as compression packing or stuffing box packing, consists of braided rings installed around pump shafts, valve stems, and other moving parts. Its primary function extends beyond simple gap sealing—it creates a controlled barrier that manages fluid or gas containment under dynamic conditions. Manufactured from materials engineered to withstand extreme temperatures and pressures, properly selected gland packing transforms potential failure points into reliable sealing interfaces. Understanding this technology isn’t just about preventing leaks; it’s about optimizing your entire system’s performance and longevity.

Why Gland Packing is a Must-Have?

Industrial systems operate under constantly fluctuating conditions where pressure change, temperature variations, and mechanical vibrations create ongoing sealing challenges. Without robust sealing solutions, even minor leakage can escalate into major operational disruptions, environmental compliance violations, and significant financial losses. Gland packing provides the adaptive sealing capability needed to maintain system integrity under these demanding conditions.

The economic advantages of gland packing become particularly evident when compared to alternative sealing methods. Installation requires minimal downtime and can typically be completed using standard maintenance tools, eliminating the need for specialized equipment or extensive training. This accessibility makes gland packing especially valuable for facilities prioritizing operational efficiency and cost management. Furthermore, the ability to adjust packing compression during operation allows for fine-tuning seal performance without system shutdown.

The controlled leakage inherent in gland packing design actually serves a functional purpose. This minimal, managed fluid flow provides essential cooling and lubrication to the packing material and shaft surface, preventing excessive heat buildup and premature wear. Engineers recognize this characteristic not as a flaw but as an integral feature that extends equipment life when properly managed. This understanding has kept gland packing relevant even as newer sealing technologies emerge, particularly in applications where absolute zero leakage isn’t critical but reliability and maintainability are paramount.

Easy to Install, But Requires Precision

While gland packing installation appears straightforward compared to mechanical seals, achieving optimal performance demands attention to detail and proper technique. The installation process begins with thorough preparation of the stuffing box and shaft surfaces, removing any corrosion, old packing residue, or surface irregularities that could compromise sealing.

Over-tightening may damage the shaft or the packing itself. If it’s too loose, leakage can occur and reduce efficiency. Proper training helps your team achieve long-lasting results. Routine checks will also help avoid future issues.

Gland Packing vs. Mechanical Seals : Which is Better?

The ongoing comparison between gland packing and mechanical seals reflects the reality that neither solution universally outperforms the other, each excels under different operational priorities and constraints. Mechanical seals offer superior sealing with minimal leakage, reduced friction losses, and longer intervals between replacements in ideal conditions. However, they demand precise installation, careful handling of delicate seal faces, and immediate replacement when failure occurs, often requiring significant downtime and specialized personnel.

Gland packing provides distinct advantages in maintenance flexibility and failure tolerance. When packing begins to leak excessively, operators can often restore acceptable performance through gland adjustment without shutting down equipment. This adjustability proves invaluable in facilities with limited maintenance windows or where process continuity is critical. The gradual, predictable wear pattern of packing allows maintenance planning based on trending rather than sudden failures common with mechanical seals.

Cost considerations extend beyond initial purchase price to encompass lifecycle expenses. While mechanical seals may offer lower operating costs through reduced leakage and power consumption, gland packing’s lower replacement cost and simpler maintenance requirements often result in superior total cost of ownership for intermittent-duty equipment or systems with frequent maintenance access. Many facilities employ a hybrid approach, using mechanical seals for critical, continuous-duty pumps while specifying gland packing for auxiliary equipment, isolation valves, and applications where controlled leakage is acceptable.

Industry Trends : Gland Packing Is in High Demand

Global demand for gland packing continues growing despite the availability of alternative sealing technologies, driven by expanding industrial infrastructure in developing economies and the massive installed base of equipment designed for compression packing.

Technological advancement in packing materials and designs addresses evolving industrial challenges while maintaining the fundamental simplicity that makes gland packing attractive. Recent innovations that enhance strength and thermal conductivity. These developments extend the operating envelope of gland packing into applications previously requiring mechanical seals.

Final Thoughts : A Small Part with a Big Impact

Gland packing may seem like a simple part—but its role is massive. It keeps systems sealed, safe, and working at full capacity. Understanding gland packing’s capabilities and limitations enables informed decisions that optimize sealing system selection for specific applications rather than defaulting to one-size-fits-all approaches.

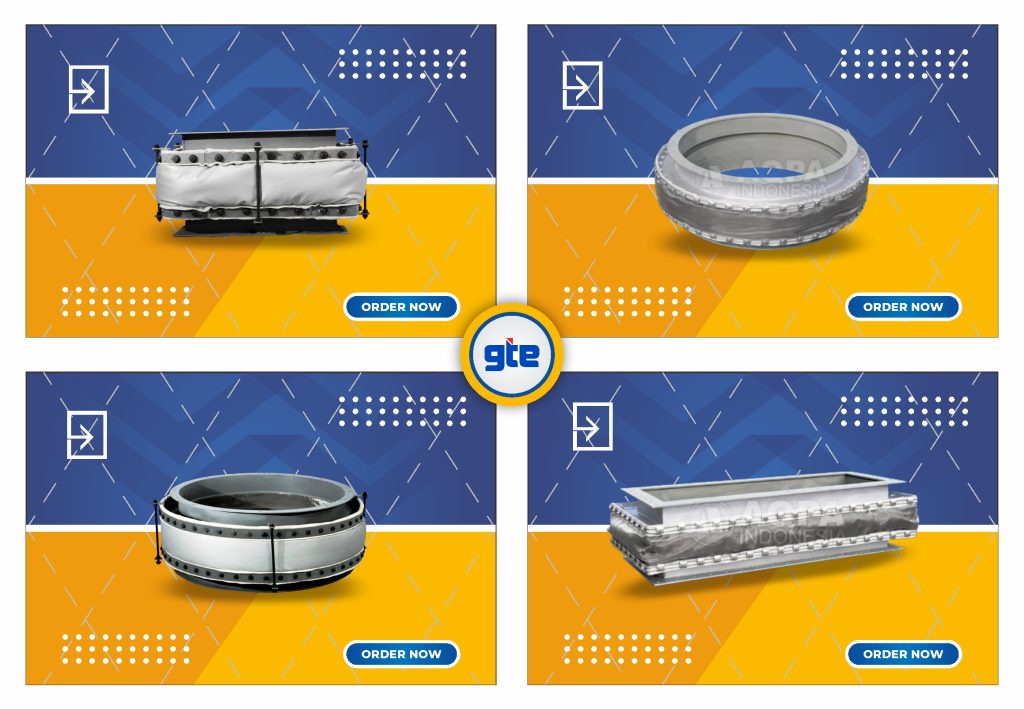

Why Partner with Us ?

We are a trusted this product provider with years of experience in the industry. We offer a wide range of this product types and sizes to meet your unique needs. Our products are made from high-quality materials and manufactured to stringent standards to ensure optimal performance and customer satisfaction.

Feel free to contact our expert team if you have any questions or wish to order this product. We are ready to assist you in finding the right solution for your application. We hope this article provides valuable insights, If you have any further questions, please do not hesitate to contact us.