What is a Flexible Metal Hose?

A Flexible Metal Hose is a flexible metal connector used in piping systems and on machinery or systems with moving parts. It is a component that offers high flexibility, withstands high pressure, and operates effectively even at cryogenic (minus) temperatures.

Its primary function is to transport liquids, gases, or even solid materials. Flexible metal hoses can handle both high-pressure and low-pressure media, from extremely low to high temperatures. Made from stainless steel, they resist corrosion, high pressure, and extreme heat.

You’ll often find them in piping systems transporting hot pressurized fluids or gases.

Benefits of Using Flexible Metal Hose

Flexible metal hoses provide numerous advantages in piping systems:

High flexibility to connect pipes that are misaligned or in hard-to-reach positions.

Compatible with various types of fittings for different applications.

Absorbs movement and prevents it from transferring to the next component, minimizing leak risks caused by vibration.

Extends the service life of the entire piping system.

Reduces maintenance costs and unplanned downtime caused by thermal expansion or mechanical movement.

These benefits make flexible metal hoses an essential part of many piping systems.

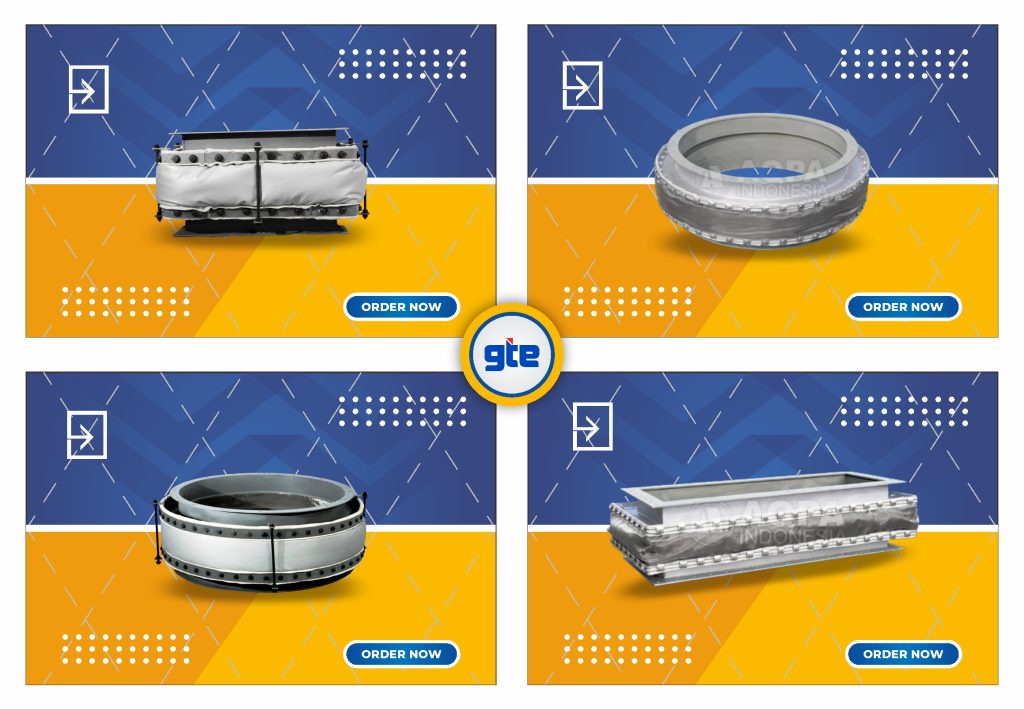

Components and Materials

A Flexible Metal Hose consists of the following parts:

Bellows – the main flexible section of the hose.

Braided layer – reinforcement around the bellows.

Ferrule – joins the bellows and braided section.

End Connection – connects the hose to the piping system.

They are typically made from corrosion-resistant stainless steel (304 or 316), capable of withstanding extreme conditions without weakening or deforming. Some models come with additional insulation or protective covers for high-temperature use.

Every unit undergoes pressure, movement, and durability testing before shipment. Precision welding and strict quality control ensure strength and reliability. Available in various sizes and configurations.

Proper Installation Guidelines

For optimal performance, follow these installation steps:

Identify the expected direction of pipe movement.

Install the hose in a neutral, untwisted position.

Use the appropriate connections (flanged, threaded, or welded).

Tighten bolts using the correct torque and sequence.

Perform a pressure test to check for leaks after installation.

Proper installation ensures maximum efficiency and system integrity.

Inspection & Maintenance Tips

Maintaining your flexible metal hose is simple but important:

Inspect connections visually every 3 months.

Look for signs of cracks or leaks.

Ensure fittings are not loose.

Clean dirt, oil, and debris from the surface.

Replace if wear or damage is detected.

With proper care, a flexible metal hose can provide years of service.

Common Industrial Applications

Flexible metal hoses are used in many industries due to their durability and performance, including:

Oil & Gas

Power Generation

Chemical Plants

HVAC Systems

Water Treatment

General Industry

Not all flexible metal hoses are created equal. Choosing the right one greatly impacts system performance. High-quality products offer:

Certified stainless steel construction.

Precision welds for maximum strength and durability.

Compatibility with various piping systems.

Performance testing under real industrial conditions.

Full technical support and documentation.

A trusted manufacturer ensures peace of mind and long-term value.

Conclusion

” A Smart Investment for Industrial Systems “

A flexible metal hose is more than just a connector—it’s a safeguard for your entire system. It prevents damage from mechanical movement, supports continuous operation, and ensures safety.

Whether in a power plant or chemical facility, this robust, reliable component keeps systems running efficiently. When properly installed, it can last for years with minimal maintenance.

To maximize system performance, start with a strong and flexible connection. Choose a flexible metal hose built to withstand the toughest conditions.

Why Partner with Us ?

We are a trusted this product provider with years of experience in the industry. We offer a wide range of this product types and sizes to meet your unique needs. Our products are made from high-quality materials and manufactured to stringent standards to ensure optimal performance and customer satisfaction.

Feel free to contact our expert team if you have any questions or wish to order this product. We are ready to assist you in finding the right solution for your application. We hope this article provides valuable insights, If you have any further questions, please do not hesitate to contact us.